HY-GP-GQ HD Series

Full-process suction high-definition printing, varnishing, drying, and die-cutting machine (Top printing type - full servo control type/segmented control type)

The entire machine is strictly designed according to high standards and high efficiency, with a human-machine integration design concept and full computer centralized control. It features multiple protection functions such as remote maintenance, fault self-diagnosis, and alarm prompts. All electrical and electronic components are selected according to European standards.

Tag:

Category:

Product Details

Overall Machine Features

◆ The entire machine is strictly designed according to high standards and high efficiency, with a human-machine integration design concept and full computer centralized control. It has multiple protection functions such as remote maintenance, fault self-diagnosis, and alarm prompts.

◆ All electrical and electronic components are selected according to European standards.

◆ The entire machine adopts a movable unit layout, with a stable and concise structure; simple operation and convenient maintenance.

◆ Printing vacuum adsorption conveying, servo-controlled phase adjustment, to ensure the requirements for high-quality, high-dot, and high-precision printing products.

◆ Equipped with infrared drying system and UV coating system.

◆ All 60mm thick transmission gears are made of high-quality alloy steel 20CrMnTi, carburized and precision ground to ensure long-term transmission accuracy. (Accuracy is approximately grade 4)

◆ All shaft rollers are made of high-quality steel, treated with quenching and tempering; dynamic and static balance correction tests are performed twice to ensure stable and reliable high-speed operation of the equipment.

◆ The entire machine uses high-quality materials and accessories. Wall panels and important components are manufactured using a machining center.

◆ Optional fixed full-servo drive control system for top printing.

Technical Parameters

| Customizable according to customer requirements | |||

| Plate Roller Diameter (including plate) (mm) | 295 | 405 | 528 |

| Machine Model (mm) | 0922 | 1224 | 1628 |

| Design Speed (sheets/min) | 360 | 320 | 280 |

| Economic Speed (sheets/min) | 200-320 | 200-280 | 150-240 |

| HD Printing Speed (mm) | 120-180 | 120-180 | 100-150 |

| Max Paper Passing Area (mm) | 900*2450 | 1200*2650 | 1600*3050 |

| Max Printing Area (mm) | 880*2200 | 1180*2400 | 1580*2800 |

| Skip Feed (mm) | 1050*2450 | 1350*2650 | 1750*3050 |

| Printing Plate Thickness (mm) | 7.2 | 7.2 | 7.2 |

| Color Registration Accuracy (mm) | ±0.25 | ±0.25 | ±0.5 |

| Slotting Accuracy (mm) | ±0.75 | ±0.75 | ±0.1 |

| Max Slot Depth (mm) | 230 | 315 | 412 |

| Min Slotting Gap (mm) | Front Knife: 225*60*225*60 Reverse Knife: 160*160*160*160 |

Front Knife: 225*60*225*60 Reverse Knife: 165*165*165*165 |

Front Knife: 245*60*245*60 Reverse Knife: 165*165*165*165 |

| Max Die-cutting Size (mm) | 850*2350 | 1150*2550 | 1550*2950 |

| Applicable Cardboard Thickness (mm) | 2-11.5 | 2-11.5 | 2-11.5 |

Detailed Introduction

Servo No-Crush Feeding Unit

◆ Adopts a servo no-crush leading edge roller feeding system, simple operation and high precision. The extension amount is adjustable, offering strong production adaptability. Increased speed transmission is more stable, suitable for warped and thin cardboard conveying, with significant effect.

◆ The servo no-crush leading edge paper feeding device uses three rows of front leading edge rollers and four rows of rear leading edge rollers for feeding. The feeding length can be adjusted arbitrarily, achieving 100% zero-pressure feeding to ensure cardboard compressive strength. The brush dust removal device uses variable frequency to adjust vacuum airflow and pressure, adapting to different cardboard sizes and warped cardboard.

◆ Pneumatic aligning device ensures accurate paper feeding and positioning. The left/right and front/back movement of the baffle are all electrically adjusted.

◆ Equipped with a powerful dust removal device to clear impurities from the cardboard surface and improve printing quality.

◆ The 10.4-inch touch screen can control functions such as machine zeroing, order changing, order saving, counting, main unit start/stop, paper feeding, and setting quantity production.

Dust Removal Unit

◆ The vacuum adsorption platform adsorbs and conveys paper. The brush roller is controlled by a servo motor, combined with an upper suction fan for powerful dust removal, and equipped with an adhesive roller to adhere dust and debris from the cardboard surface.

Servo Top No-Crush Feeding Unit (Optional)

◆ Adopts a top suction design, combined with multi-axis servo motor control.

◆ Combines cardboard conveying with dust removal. A powerful suction box removes surface dust and paper scraps before cardboard printing, effectively reducing print defects (white spots).

◆ Compared to traditional pressure roller conveying, the servo top no-crush feeding conveyor rollers and printing rollers are on the same level, making cardboard conveying smoother, improving feeding accuracy for warped cardboard, and resulting in more exquisite printing.

◆ Compared to traditional models, the servo top no-crush feeding only requires two suction fans, making it more energy-efficient.

Reasonable and practical structure, large reserved space below, convenient for maintenance and upkeep.

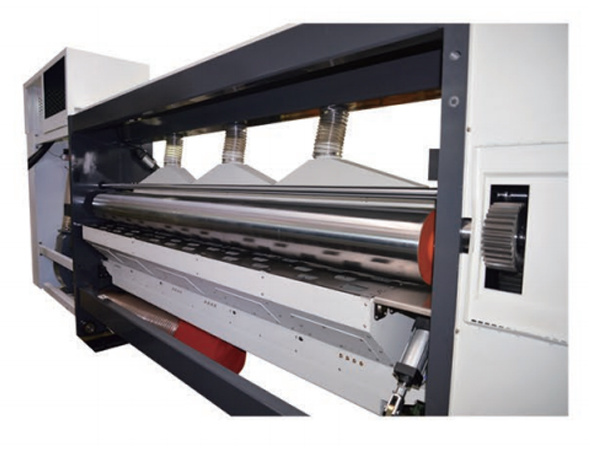

Printing Section

The printing roller and impression roller are both made of high-quality steel, surface ground and hard chrome plated.

Dynamic and static balance operation correction test, smooth high-speed operation.

Printing phase uses servo drive, touch screen display for adjustment.

Adopts plate hanging mechanism, with plate registration adjustment function, convenient and fast operation.

Loading and unloading of printing plates are equipped with foot switch control for forward and reverse rotation, quick adjustment.

Equipped with functions such as automatic zeroing, memory, and reset.

Anilox roller and impression roller gap automatically adjusted by touch screen display input values.

Plate roller lateral position movement electrically adjusted, adjustment range ±8mm.

Vacuum paper feeding bellows, air volume and pressure in each section automatically adjusted pneumatically.

Equipped with air knife drying system, which can improve printing speed and quality.

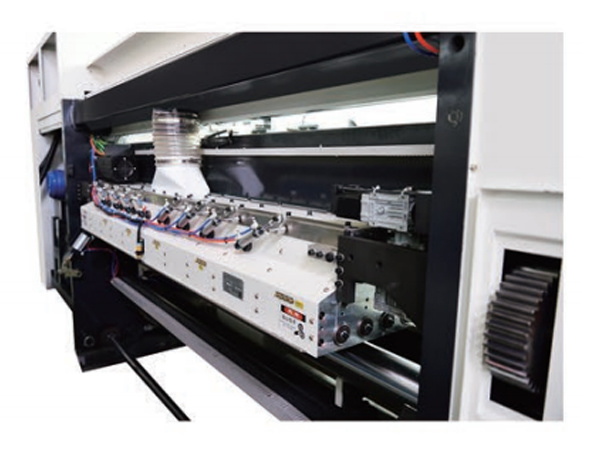

High-line ceramic anilox roller combined with pneumatic ink doctor blade system ensures high-quality printing requirements.

Single doctor blade ink supply system effectively reduces the adverse effects of dust on the anilox roller surface, and while ensuring quality, it solves the ink leakage phenomenon caused by improper operation of double doctor blades.

Specially made aluminum alloy arc-shaped doctor blade chamber, increasing bending resistance by 30% and saving 20% in ink supply storage.

Lined with a tetrafluoroethylene (PTFE) eco-friendly layer, which allows for easy cleaning and non-sticking to the chamber.

Vacuum suction assisted roller conveying cooperates with the impression roller, ensuring printing color registration accuracy up to ±0.35mm.

Drying Section

Vacuum conveying ensures paper feeding accuracy.

Infrared drying system, adjustable drying temperature, segmented control of drying area, convenient adjustment, saving electricity.

Linear guide rail positioning controls the lifting of the air box, making high-speed operation more stable.

Strong compatibility, can also meet various product requirements.

Has shutdown protection function, reduces shutdown cooling and restart waiting time, enhances safety factor, and improves production efficiency.

The fixed unit of the drying section is widened, which helps with the drying speed of the varnish.

Varnishing Section

During production, the varnishing unit can choose between water-based varnish or UV varnish for varnishing, and can also be used as a printing unit.

Equipped with paper jam sensor for safer and more reliable operation.

Full Computer Die-cutting and Slotting Section

Five sets of steel cutting dies, which can replace slotting and corner cutting, trimming, oblique mouth boxes, etc., making slotting and corner cutting accurate and aesthetically pleasing.

Correspondingly configured with pre-pressing, creasing, and forming three-stage creasing devices. Pre-pressing uses a large-arc steel wheel; the forming upper wheel includes a urethane layer, and the lower wheel is a single-line steel wheel, making the cardboard less prone to damage and ensuring good line linearity. The pre-pressing wheel, creasing wheel, and forming wheel adopt PLC control with 5 servo adjustments. The plate-free slotting die adopts PLC control with 5 servo tracking positioning, full computer one-key order change, and automatic plate registration, which is convenient and fast.

This device achieves multi-purpose functionality, reduces slotting units, and lowers processing costs.

Fully Automatic Paper Feeder

Reduce Costs: Single-person operation reduces the number of workers, effectively lowering labor costs for enterprises and reducing worker labor intensity.

Improve Efficiency: Can effectively increase machine speed and improve work efficiency.

Reduce Waste: Reduces the number of times workers touch the cardboard, thereby reducing damage to the cardboard from manual intervention.

Stable Performance: Adopts a relatively mature hydraulic system, with a gear motor providing power, stable and durable.

Simple Operation: Buttons use a graphical interface, easy to recognize, and can be operated upon getting on the machine.

Inquire Now

If you are interested in our products, please leave your email, and we will contact you as soon as possible, thank you!